Table of Contents

Double nozzle / Shift head valve

Part number: 1101201

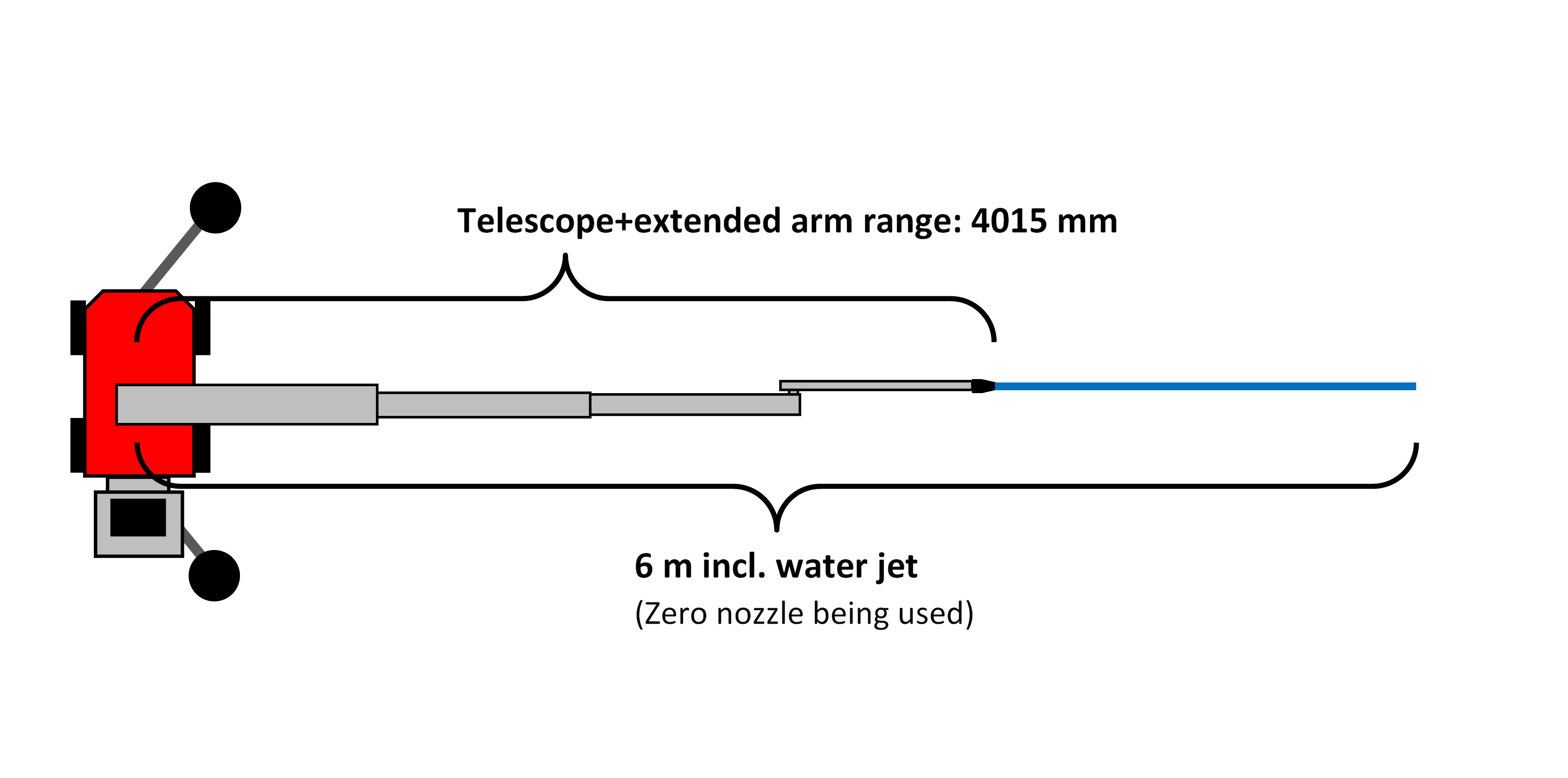

The double nozzle is equipped with a rotary nozzle and a 0-degree nozzle. This double nozzle is used to reach further in deep pens. The 0-degree nozzle can reach up to six meters. However, use the rotary nozzle as much as possible if your robot is equipped with the double nozzle. The rotary nozzle are the most efficient one to use. Only use the 0-degree nozzle to reach the end of the pen.

It's very important to program the robot correctly if you robot is equipped with a double nozzle. If not, there may come water from the wrong nozzle.

How the double nozzle works

The double nozzle has a steel ball inside. The steel ball can move with the gravity when the water is turned off. This means that the nozzle has to be in a certain angle to make sure that the water comes from the correct nozzle when we switch the water on. The nozzle that has the steel ball closest to it will receive the water.

When the rotary nozzle is placed straight down (and arm position approx. 45 degrees or 135 degrees from the boom) the steel ball will fall down towards the rotary nozzle. The steel ball will in this case block the 0-degree nozzle which means that the rotary nozzle will be the one who receives the water when it's turned on.

When the rotary nozzle is placed straight down (and arm position approx. 45 degrees or 135 degrees from the boom) the steel ball will fall down towards the rotary nozzle. The steel ball will in this case block the 0-degree nozzle which means that the rotary nozzle will be the one who receives the water when it's turned on.

Same if the 0-degree nozzle is placed straight down.

Once the water is turned on the steel ball will lock in this position and the water will come through the same nozzle until the water is turned off.

How to switch nozzle when programming

It's important to move the robot in a certain way to guarantee there will come water through the nozzle you want to change to. Here is how you switch the nozzle when programming. The instruction shows when the robot change from rotary nozzle to 0-degree nozzle. But it's the same process to go from 0-degree nozzle to rotary nozzle.

1. Switch the water off with the button on the joystick.

2. Rotate (if necessary) the nozzle so the correct nozzle is placed straight down. You might have to adjust the arm position as well (arm position should be approx. 45 degrees or 135 degrees out from the boom).

4. Make a movement with the boom or tower that lasts for 5 seconds without water on. This will give the steel ball time to fall down and block the other nozzle.

- The water can with suction power hold the steel ball if we just turn the water off and place the nozzle in the right position. This means that the water will come back out from the nozzle we just used if the procedure is made to quick. The 5 seconds movement with the tower or boom is to prevent this from happening.

This picture shows when we moved the tower from the right side to the left side of the pen.

5. Turn the water back on with the button on the joystick.

When you are using the 0-degree nozzle, be as efficient as possible. Do not overdo the program. Remember to keep the program short and efficient.